Cyclone separator made of metal / welding kit

Product number:

9022

Product information "Cyclone separator made of metal / welding kit"

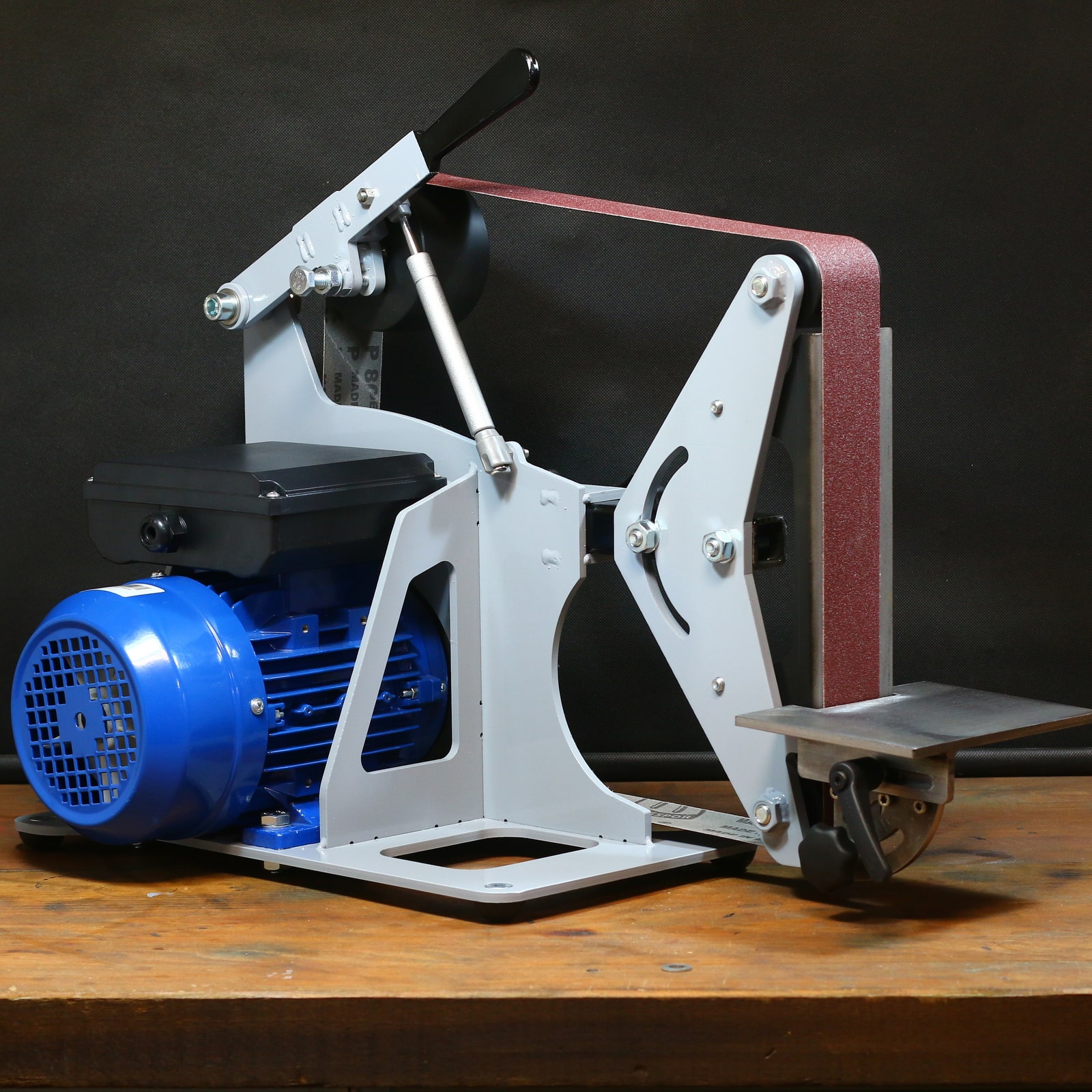

With this welding kit you can create a metal cyclone separator. The advantage of a metal cyclone is that it can even suck up glowing sparks from a grinder. We use this metal cyclone on our BS1500 belt sander to extract hot sparks while grinding metal. The separator has two 40mm connections at the top and a flange plate at the bottom for mounting on a metal bucket. The steel cyclone kit is made from precisely cut 1.5 mm thick sheet steel and contains two pipe sections for the vacuum cleaner connections. Assembly is extremely easy as the sheet has pre-cut bending cutouts and can be bent by hand and then welded. When vacuuming metal chips, we recommend not using a plastic suction hose at the entrance to the cyclone due to the possible formation of sparks. Instead, you should use a stainless steel corrugated pipe. A plastic hose can be attached to the outlet.

Metal cyclone dimensions

- Height: 300mm

- Diameter: 180mm

- Vacuum cleaner connection: 40mm

- Flange diameter: 140mm

How does a cyclone work?

A cyclone separator is a powerful device for cleaning sucked-in air. Its revolutionary design is based on the principle of cyclone technology, which enables efficient separation of dust and dirt.

The process begins with the cyclone vacuum sucking air through an inlet. This air flow carries dirt particles, dust and impurities with it. Once the air enters the device, it is directed into a funnel-shaped container. In the cyclone, the air rotates at high speed and due to the centrifugal force, the heavier dirt particles are pushed outwards and deposited into the container.

The cleaned air, which is now almost free of dust and dirt, is led back into the room through an outlet.

Another advantage of our cyclone is that it is made of metal and can therefore suck up hot chips or sparks.

Manufacturer "Bengs Modellbau"

Hersteller

Bengs ModellbauIm Kirchfelde 6

31675 Bückeburg

info@bengs-modellbau.de

Verantwortliche Person

Patrick BengsBengs Modellbau

Im Kirchfelde 6

31675 Bückeburg

info@bengs-modellbau.de

Related links of the manufacturer

Login