Ericsson Hot Air Pump Stirling engine

Product information "Ericsson Hot Air Pump Stirling engine"

The original Ericsson Hot Air Pump

The Rider-Ericsson hot air engine was probably the most successful Stirling engine in the world at the time. It was produced from around 1880 to 1915. The Stiling engines were used in small companies, hotels and on farms as pumping machines to pump water. The hot air engine pumped the water to high water tanks or water towers where it was stored for later use. Or the Rider-Ericsson was used to irrigate meadows and fields - the water produced also served as cooling water for the Stirling engine. The Rider-Ericsson hot air machine was able to pump 700 liters of water per hour 15m high while consuming 1.5 kilos of coal. It could be fired with wood, coal, gas or petroleum. The Rider-Ericsson hot air machine was easy to use and very easy to maintain.

The model

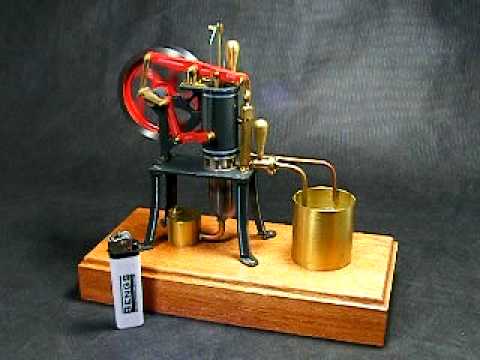

The Stirling engine “John” is a model replica of the Rider-Ericcson Hot Air Pump machine and is available here as a material kit. The entire structure consists of the Stirling engine, the burner, a pump and a water reservoir. The Stirling engine is a Stirling with a beta configuration in which 2 pistons run in one cylinder. The burner is an alcohol burner with a fiberglass wick. On the one hand, the pump is used to cool the cylinder, but it can also be used to pump the water. In this model structure, the water reservoir serves as a storage container for the cooling water. All components are mounted on the included wooden plate.

The material kit contains all the parts required for construction and operation, detailed construction instructions and drawings. The special thing about the kits from Bengs Modellbau is that all the milled parts are already milled. All you need is a small lathe, hand tools and a small drill. The flywheel has a diameter of 80mm and is already pre-turned. The oak base plate is 255mm long and 120mm wide and is also included.

Dimensions of the Rider-Ericsson Stirling engine "John":

- Base plate: 255mm x 120mm

- Flywheel: 80mm

- Total height: 120mm

- Working piston: 18mm

- Displacer piston: 16mm

To build the Stirling engine "John" material set, you will need a small lathe, a small drill and a gas burner for soldering small parts. Otherwise there are hand tools that should be in every “steam engine workshop” (tap M2, M3, M5x0.5 and M8x0.75 dies M2 and M3, M5x0.5 and M8x0.75 reamer 2H7, 3H7, 5H7, 6H7, files , twist drill set) is necessary.

The scope of delivery of the Stirling engine John material kit includes:

- Finished milled parts

- Raw material for the turned parts

- Milled and pre-turned flywheel with curved spokes

- Wooden base plate (oak)

- Material for the burner

- Material for the cooling water pump

- All required screws, nuts, ball bearings and O-rings

- Construction plan Stirling engine John drawings (10 sheets) and construction instructions (4 sheets)

Hersteller

Bengs ModellbauIm Kirchfelde 6

31675 Bückeburg

info@bengs-modellbau.de

Verantwortliche Person

Patrick BengsBengs Modellbau

Im Kirchfelde 6

31675 Bückeburg

info@bengs-modellbau.de

Login