Flux for silver solder

€8.00*

Available, delivery time: 1-3 days

Product information "Flux for silver solder"

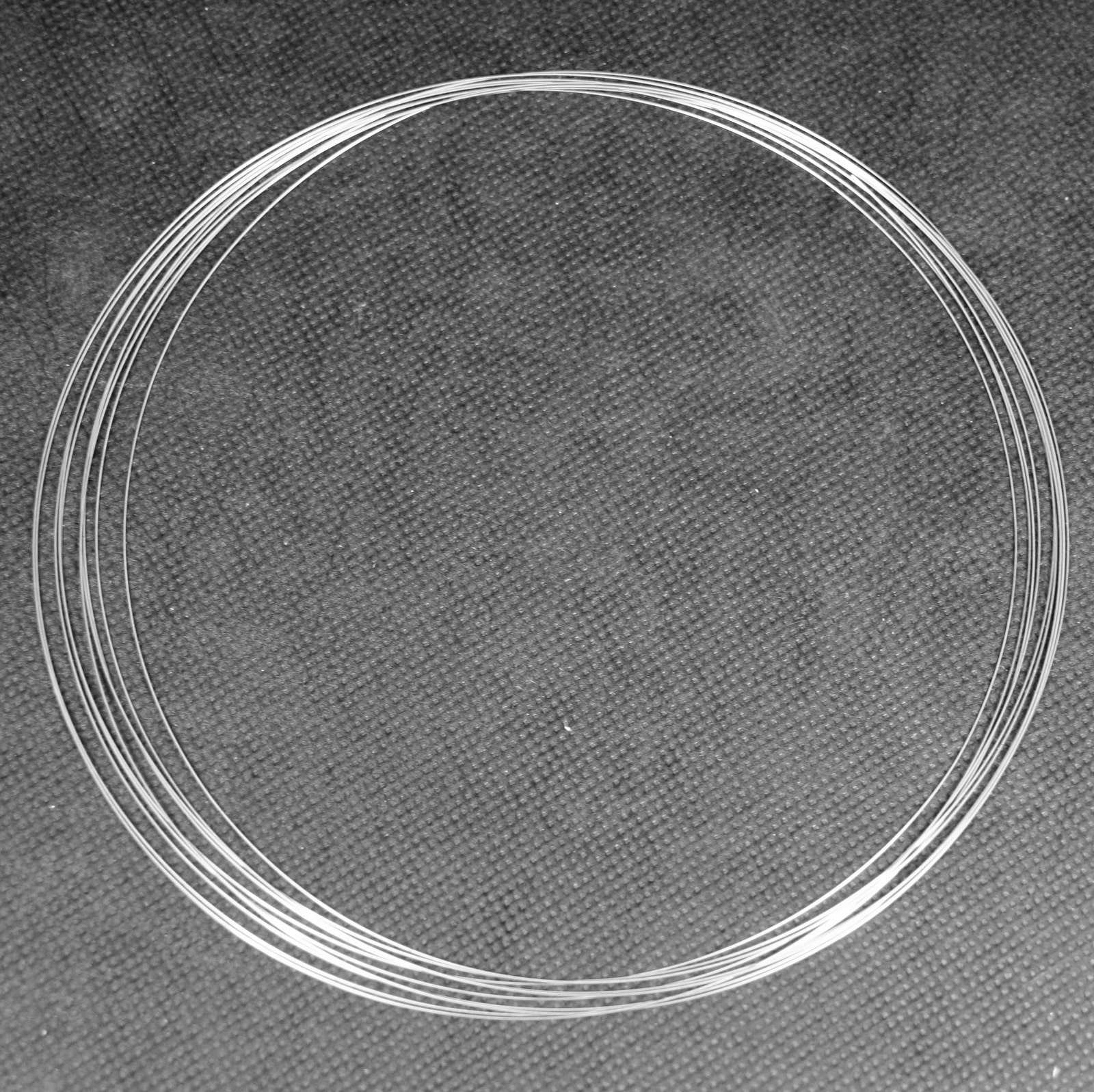

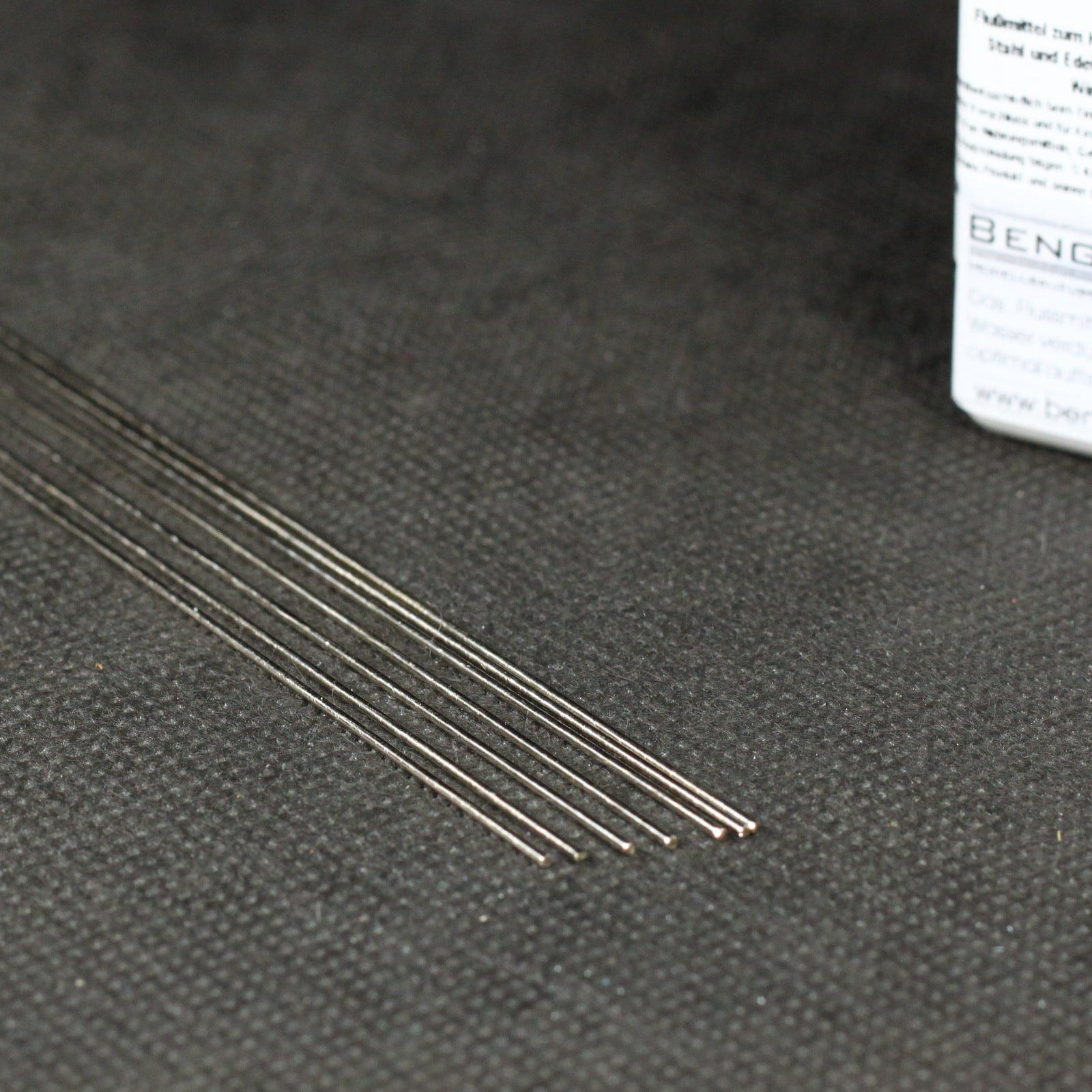

When brazing, fluxes have the task of loosening and removing the oxide layers present on the soldering surfaces and preventing them from forming again during soldering. The flux is adjusted to the working temperature of our Silver hard solder matched. Before use, the flux for silver solder should be stirred well. Using the brush in the bottle, a thin layer can be applied to the component to be soldered. You can find detailed instructions in our model making magazine (Hard soldering with silver solder instructions). If the silver brazing flux has dried out, you can make it liquid again with distilled water. Brazing with silver solder rods without flux is not possible.

When the flux is heated with the burner, the water it contains first evaporates. This can be seen in the final formation of small bubbles. When the component is heated further with the flux and the working temperature is reached, the flux paste begins to melt and becomes transparent. Now the moment has come where the silver solder can be added.

- The effective range of the flux for silver solder is between 500°C and 800°C.

- The flux is suitable for brazing copper, brass, gunmetal, steel and stainless steel.

Tip: Flux residues and discoloration of the material can be optimally removed with our Satin brushes or remove with abrasive fleece.

You can get the flux for silver solder from us in the packaging sizes:

- 50g. Bottle with brush

- 100g.Bottle without brush

Hersteller

FELDER GMBH Löttechnik

Im Lipperfeld 11

46047 Oberhausen

info@felder.de

Verantwortliche Person

FELDER GMBH LöttechnikIm Lipperfeld 11

46047 Oberhausen

info@felder.de

Login