About us

Excerpt from the magazine Maschinen im Modellbau, the specialist magazine for technical model making, steam engines, engines and workshop practice. With the kind permission of the machines in the VTH model making department - www.vth.de

Company portrait Bengs Modellbau

Author: Kurt Becker

Some people dream of turning their hobby into a career, but very few manage to do so. One person who made this happen is Patrick Bengs, who has been a household name among us model makers for years.

Even as a teenager, the young Patrick was building models, including model airplanes, ship models and steam engines. Since his father worked in metalworking and there was also a lathe in the Bengs family home, he succeeded in building steam engines. And so young Patrick almost inevitably learned the profession of industrial mechanic. But model building just didn't let him go and at some point he sold a self-made steam engine on Ebay. That was the initial spark for a business idea! In 2003, Patrick Bengs founded a small company for technical model making, which he ran as a sideline. Great success came very quickly and just two years later, in 2005, we made the leap into full independence with

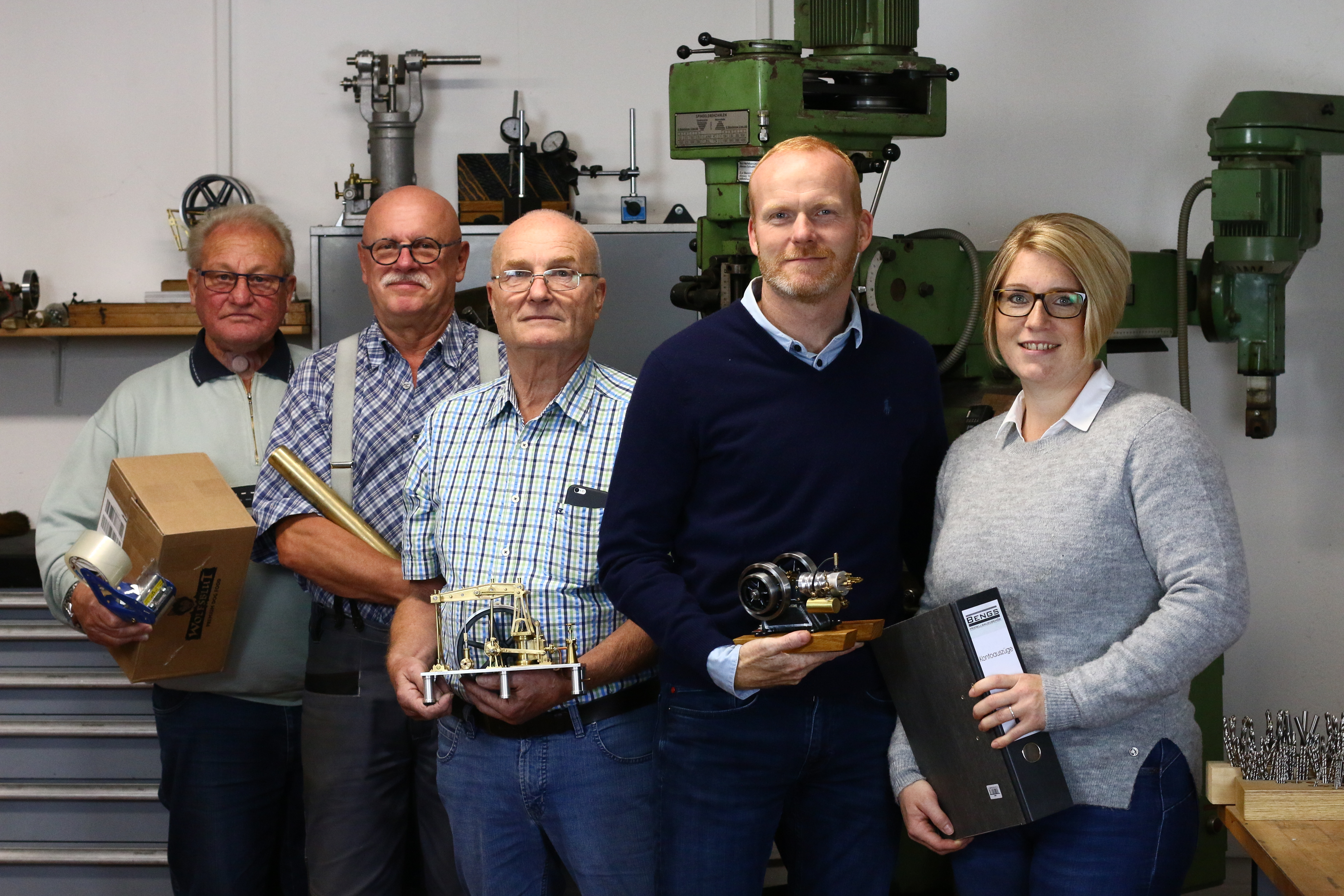

announced in the model making division. The Bengs company is a typical family business: Bengs itself is, of course

central figure, his wife takes care of the inevitable office work, his lively father still works hard and two part-time employees complete the team. They are responsible for shipping, assembling the material sets and sawing the semi-finished products to size for the model kits. The Bengs range includes material kits for steam engines, flame eaters, Stirling engines and combustion engines, but also tools for model making as well as accessories and various semi-finished products.

It is a specialty of Bengs to supply material kits that contain the necessary milled parts prefabricated. In doing so, he addresses a difficulty that many model makers face: You have a lathe but no milling machine, let alone a CNC milling machine. And if the model maker fails to process a milled part during further processing, that's no problem. Bengs can deliver individually. For the turned parts, Bengs includes the necessary semi-finished products as well as all the small parts, such as seals, screws, etc. and of course the drawing documents with detailed construction descriptions. In 2015, Bengs expanded his range when he took over the casting kits from Ravensburger Dampfmodellbau (Probst). These are large models of combustion engines that require model makers to use correspondingly large lathes and milling machines. Bengs himself was initially skeptical as to whether these models could be sold in sufficient numbers. But to his own surprise, this was the case. The development of a new model takes around a year. About half of this happens on the computer with CAD and the other half through tinkering and testing in the workshop. He gets his ideas for new models on the Internet and through his own inspiration. First, a provisional drawing and a preliminary prototype are created. A number of changes and improvements have already been incorporated into the second prototype model. Some designs that look good on the computer are not, in practice, as expected. Only the third pre-production model largely corresponds to the final version and then the necessary set of drawings is created.

Bengs senior then acts as a test model maker to check whether everything is ok and the model can now be produced as a kit. Then such a model kit goes into production. The milled parts are manufactured in-house at Bengs, using three CNC milling machines. Bengs only sources the castings from outside. There is partial collaboration with his colleague Thorsten Schür. Of course, the customers come primarily from German-speaking countries but also from abroad. The focus countries are the Netherlands, the USA and Australia. Bengs reaches customers exclusively via the Internet. He no longer attends trade fairs; the time and financial investment involved is disproportionate to his success. At a trade fair you can reach a few stand visitors, on the Internet you can reach the whole world... Of course, this requires an appropriately designed homepage, which Bengs also has available in an English version.

A homepage is a company's business card and Patrick Bengs designs it himself. And this homepage is really impressive: all of his models are described in detail, there are many pictures of the construction of each model and detailed assembly videos. There are also lots of tips and videos on various problem solutions. These videos have the great advantage for customers that they can find instructions and help even after business hours, and if you get stuck with them, Patrick Bengs is happy to help on the phone. The customer base consists primarily of the 60+ generation. He even has customers who are well into their ninth decade of life and who place their orders online in a timely manner. But he also observes that the number of younger customers, i.e. under 60, is slowly increasing. He makes another interesting observation: older customers are more into steam engines, younger ones prefer combustion engines.

The corona pandemic has caused heavy losses for many companies. If anything, it helped the model making division. So for Bengs the otherwise inevitable summer slump was hardly noticeable. The busy person stands in his company all day, answers questions on the phone, works in the workshop, develops new models, maintains and expands the homepage and so much more. With so much commitment, does he still have time for a hobby? Yes, he does, he takes care of his classic car. And so the author of this report, also on behalf of all model building enthusiasts, wishes him continued success and joy in his work. This report is based on a very long telephone conversation with Patrick Bengs. The pictures are all from Bengs himself, thank you very much.

More information: www.bengs-modellbau.de

With kind permission of the machines in the VTH model making - www.vth .de