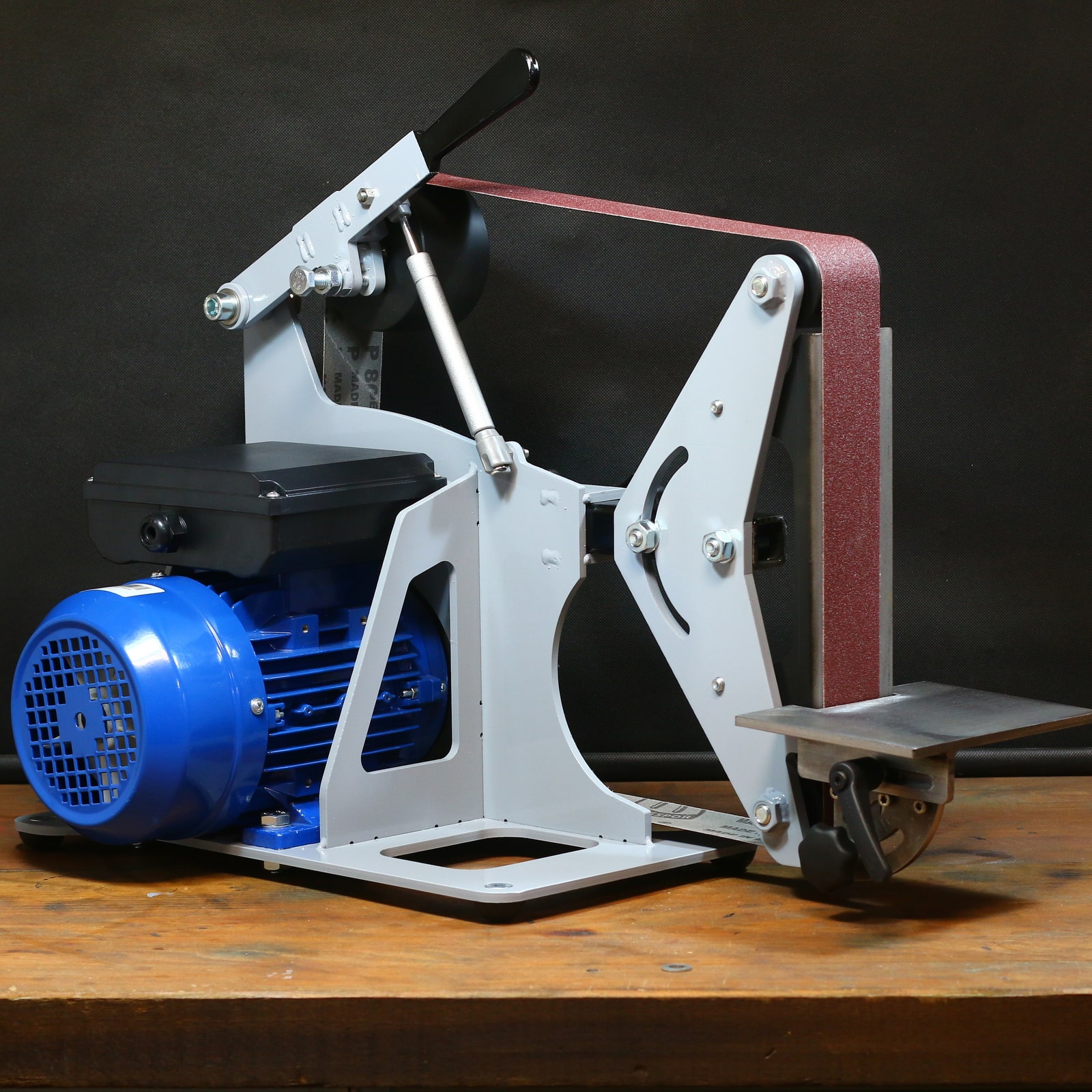

Spark arrester for BS1500 belt sander welding kit suction tray

Product number:

9021

Product information "Spark arrester for BS1500 belt sander welding kit suction tray"

This chip catcher is compatible with our BS1500 belt sander and is installed directly under the work table. A large part of the grinding chips is automatically fed into the 1.5 mm thick sheet metal funnel. The chip catcher has a vacuum cleaner connection with an outer diameter of 40 mm. On older models, the attachment can be attached to the machine base by drilling an additional mounting hole, while on the current model this hole is already present.

The chip catcher kit is supplied from precisely cut 1.5 mm sheet steel, together with a pipe section for the vacuum cleaner connection. Assembly is extremely uncomplicated, as the sheet metal can be formed by hand using pre-punched bending cutouts and then welded.

When vacuuming metal chips, it is recommended not to connect a plastic suction hose directly to the chip catcher due to the possible formation of sparks, but instead Use a stainless steel corrugated pipe. We also recommend using our metal cyclone to ensure that no glowing sparks can enter the vacuum cleaner.

Dimensions of chip catcher

- Inlet funnel: 120mm x 120mm

- Connection vacuum cleaner: 40mm outside

Manufacturer "Bengs Modellbau"

Hersteller

Bengs ModellbauIm Kirchfelde 6

31675 Bückeburg

info@bengs-modellbau.de

Verantwortliche Person

Patrick BengsBengs Modellbau

Im Kirchfelde 6

31675 Bückeburg

info@bengs-modellbau.de

Related links of the manufacturer

Login