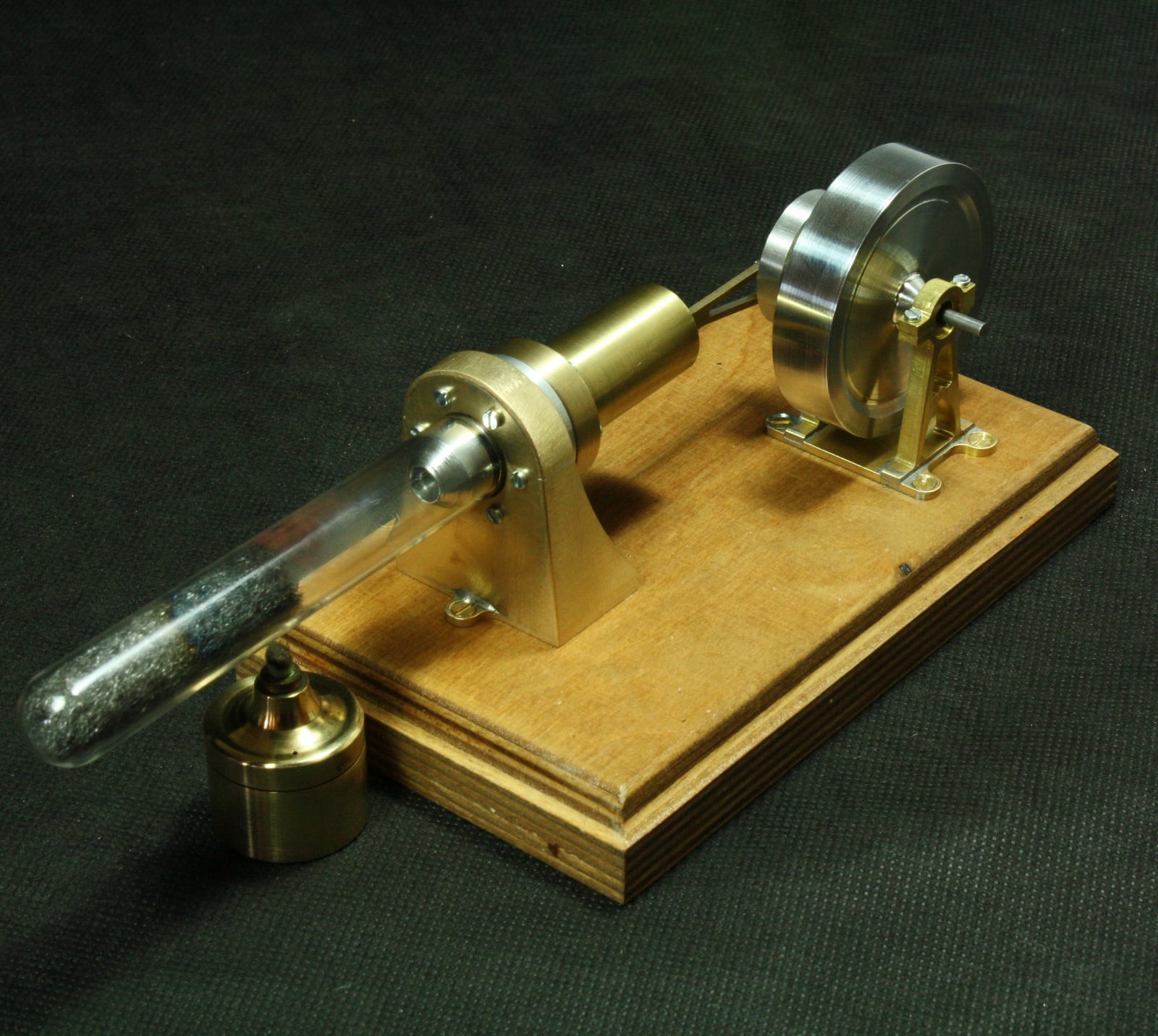

Thermoacoustic Stirling engine Rufus

Product information "Thermoacoustic Stirling engine Rufus"

Our model Rufus is a model of a thermoacoustic Stirling (Lamina Flow Stirling). The construction of the thermoacoustic Stirling engine is very simple. In Rufus, the working piston is moved by a thermoacoustic effect. A thermoacoustic effect occurs when air is heated in a tube and caused to vibrate using an exciter source (e.g. steel wool) so that a standing wave is formed in the tube (Rijke tube). As with the Stirling engine, there is also the cycle of expanding and contracting air (gas). A comparison with the Stirling engine is also possible in that it is a closed system, although the thermoacoustic Stirling does not use a displacer piston. This is what makes the design of the engine so simple. The thermoacoustic Stirling engine Rufus runs almost silently. It is heated with a small burner filled with spirit. The working piston is made of graphite and does not need to be lubricated.

The Stirling engine 'Rufus' material kit is constructed according to the well-known BENGS model building principle. All milled parts are prepared to such an extent that they only need to be deburred and possibly drilled. The turned parts are unprocessed. The flywheel can also be made on a small lathe.

The scope of delivery includes:

- Finished milled parts

- Raw material for the turned parts and graphite pistons

- Raw material flywheel (aluminum)

- Milled wooden base plate made of oak

- Material for the burner

- All required screws, nuts, glass tubes, fiberglass wick, ball bearings and O-rings

- Construction plan Stirling engine Rufus drawings (6 sheets) and construction instructions (2 sheets)

Dimensions Thermoacoustic Stirling engine Rufus

- Base plate: 170mm x 100mm

- Flywheel: 60mm

- Total height: 88mm

- Total length: 255mm

- Working piston (graphite): 18mm

To build the thermoacoustic Stirling engine Rufus material set, you will need a small lathe (min. Opti D180 x 300), a small drill and a gas burner for soft soldering. Otherwise, hand tools, which should be in every “steam engine workshop”, are required (M2 tap, 3H7, 6H7 reamer, files, drill set, screw locking adhesive).

Hersteller

Bengs ModellbauIm Kirchfelde 6

31675 Bückeburg

info@bengs-modellbau.de

Verantwortliche Person

Patrick BengsBengs Modellbau

Im Kirchfelde 6

31675 Bückeburg

info@bengs-modellbau.de

Login