Valve controlled steam engine Isabel

Product information "Valve controlled steam engine Isabel"

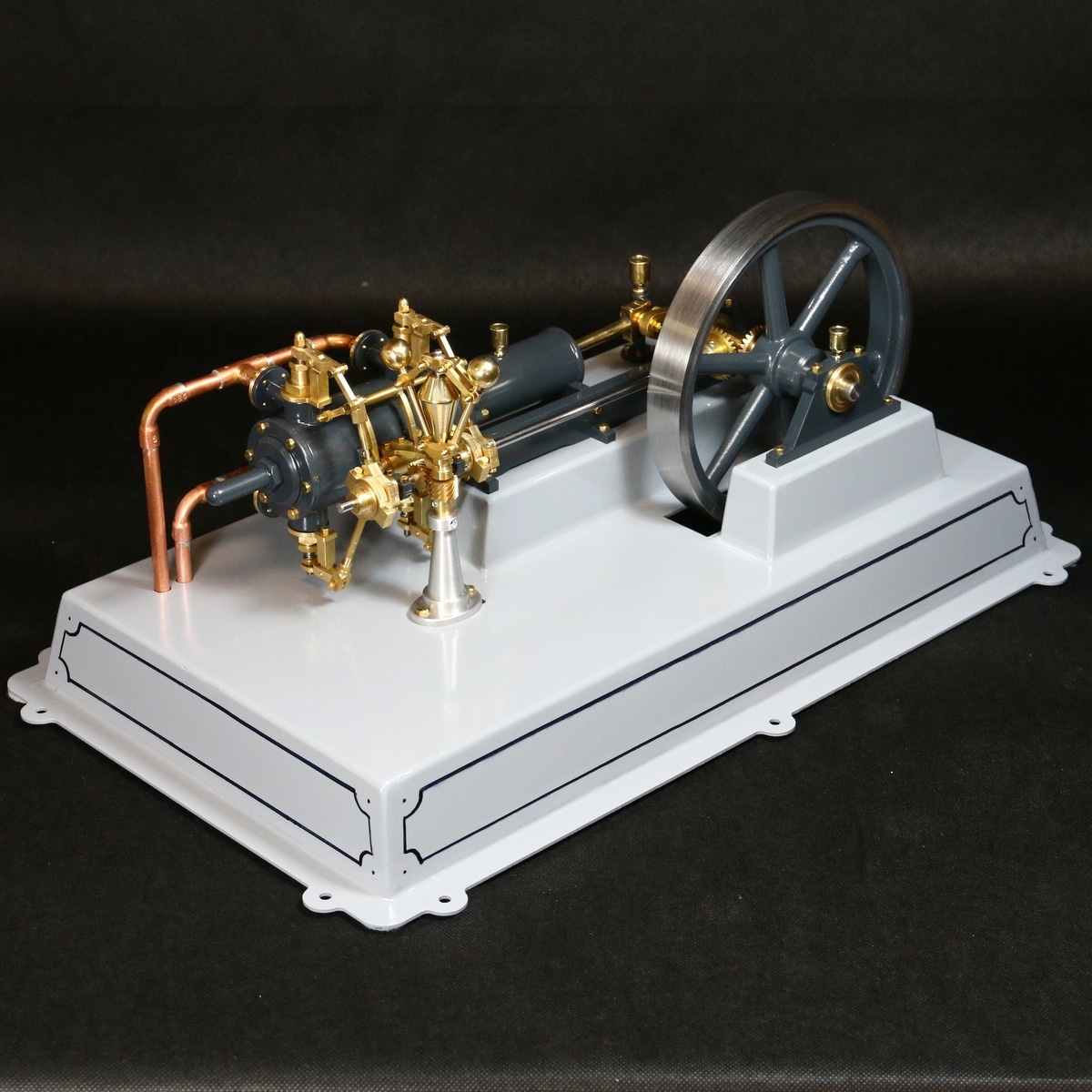

Valve-controlled steam engines are certainly among the most impressive machines. Since the valve control is attached to the outside of the cylinder, the process can be observed very well. The centrifugal governor increases the number of moving parts even further. A slow-running valve-controlled steam engine with a centrifugal governor is a real treat for every model maker.

With this material kit you get, as usual, all the parts you need to make this beautiful valve-controlled steam engine. All milled parts are already milled. All turned parts are included in the kit as raw material and must be made by you according to the drawing that is also included.

A valve-controlled steam engine has a particularly impressive control system. The distribution of the steam is not controlled by a compact valve but by 4 individual valves. Each of the valves has its own eccentric. In our machine, the centrifugal governor controls the speed by accessing the valve rods and limiting their travel.

The model

With this material kit for the valve-controlled steam engine ‘Isabel’, you can build a very complex valve-controlled steam engine. The kit has a stable machine base made of sheet steel. The majority of the engine parts are made of brass. The 4 eccentrics of the steam engine are driven by 2 brass bevelled wheels. The centrifugal governor is driven by two diagonally toothed brass gear wheels. It can be used to regulate the speed of the steam engine.

The cylinder of the valve-controlled steam engine is made of brass, the piston and plain bearing bushes are made of bronze. The 140mm flywheel is made from a very cleanly cast steel casting. The base plate is laser-cut from 1.5 mm sheet steel that can be easily bent by hand. All other parts are made of brass, as proven in steam modelling.

The following is required for construction:

To build the horizontal steam engine you will need a lathe, a small drill and a gas burner for soft soldering. Furthermore, hand tools are required, which should be in every "steam engine workshop" (tap M2, M3, M5x0.5, M6x0.75, M10x1 / dies M2, M3, M5x0.5, M6x0.75, M10x1 / reamers 3H7, 4H7, 8H7, / files, drill set).You can find more information about building this steam engine in our model building magazine. In our magazine you will find a construction report of the horizontal valve-controlled steam engine "Isabel" with many pictures and explanatory texts. This means you can find out about the construction in advance and also find suggestions and support during the construction phase.

The scope of delivery includes

- finished CNC milled parts

- Raw material for the turned parts

- Raw cast part for the flywheel

- Laser cut for base plate

- All required screws, model building nuts and springs

- 1 set of bevel gears, 1 set of helical gears

- Drawings of valve-controlled steam engine “Isabel” (18 sheets) and construction instructions (7 sheets)

Dimensions of the model building steam engine “Isabel”:

- Height with base plate: 170mm

- Length with base plate: 250mm

- Width with base plate: 420mm

- Piston diameter: 20mm

- Flywheel diameter: 140mm

- Stroke: 36 mm

- Weight of the finished machine: 4.4 kilos

Hersteller

Bengs ModellbauIm Kirchfelde 6

31675 Bückeburg

info@bengs-modellbau.de

Verantwortliche Person

Patrick BengsBengs Modellbau

Im Kirchfelde 6

31675 Bückeburg

info@bengs-modellbau.de

Login