Lexicon: B

Balanciermaschine

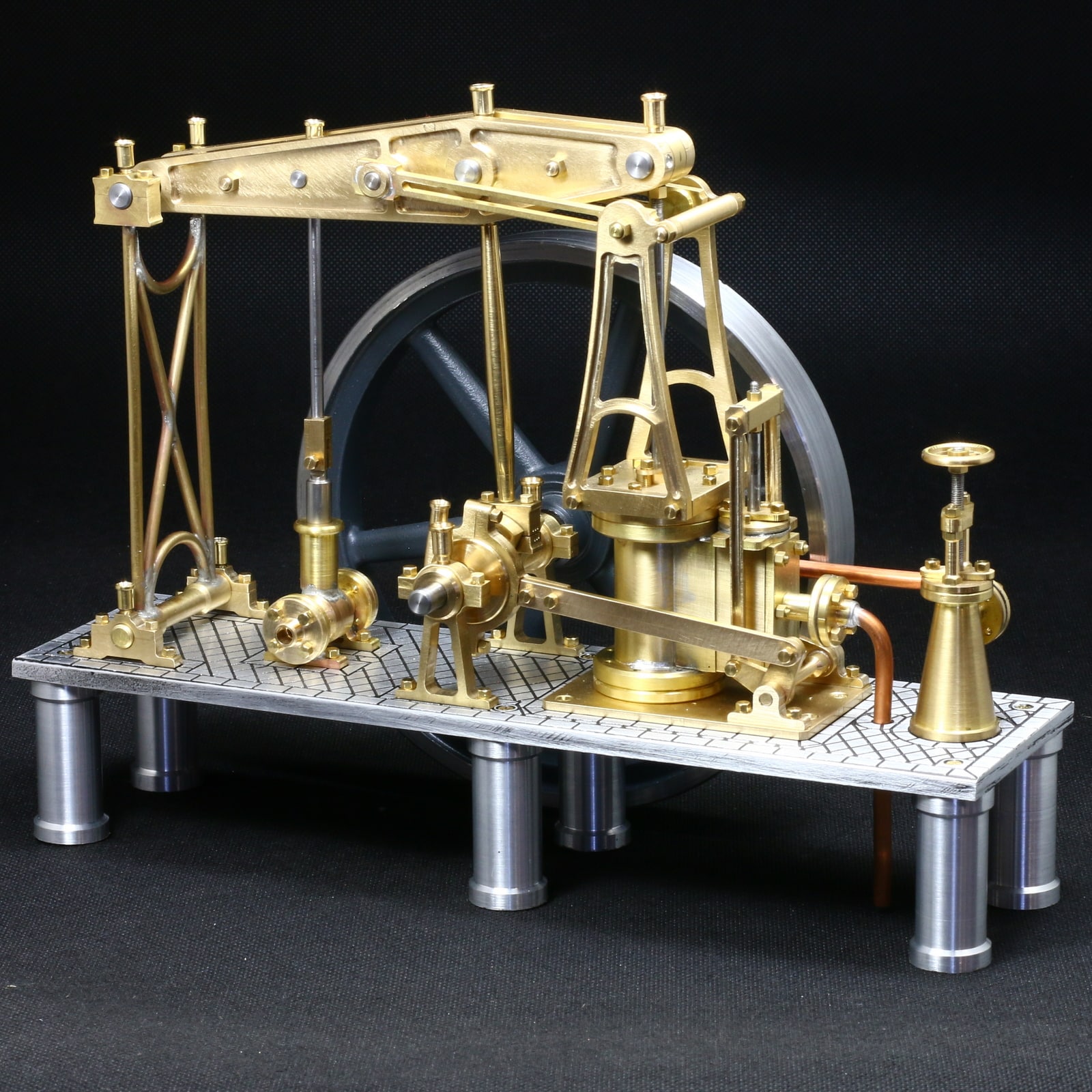

Die Balanciermaschine ist eine Dampfmaschine wie sie zum Anfang der Viktorianische Ära und zu Beginn der Industrialisierung verwendet wurde. Ihren Namen erhält sie von dem mittig gelagerten Balancierbalken, der sich quer über die Balanciermaschine erstreckt und der die erzeugte Kraft über Gestänge weiterleitet. Sie ist mit einem Wattschen Parallelogramm ausgestattet, welches für eine gerade Kolbenstangenführung genutzt wird.

Die Balancierdampfmaschine beruht auf dem Funktionsprinzip der Kolbendampfmaschine. Sie setzt Energie (den Dampfdruck) in mechanische Energie (Rotationsenergie) um. Ein Kolben bewegt sich dabei, im dazu gehörigen Zylinder, hin und her. Der Druck des Dampfes bestimmt die Geschwindigkeit des Arbeitstakts und somit auch die Drehzahl für das Schwungrad. Die Rückbewegung bei einseitig beaufschlagten Kolbenarten geschieht aus der gespeicherten Rotationsenergie bzw. Schwungenergie. Hingegen bei zweiseitig beaufschlagten Kolben geschieht dieses als separater Arbeitstakt. Die Zuführung des Dampfes steuert im Original meistens ein Muschelschieber. Bei Modellbaudampfmaschinen kommt neben dem Muschelschieber auch oft ein Rundschieber zu Einsatz. Die Dampfmaschine und ihr Arbeitsverfahren ist somit in zwei Takte aufgeteilt, d.h. Sie arbeitet im Zweitaktverfahren.

Dampfmaschinen gab es und gibt es in den unterschiedlichsten Größen. Heute kann man sie in meist in Museen oder als voll funktionsfähige Modelle bewundern. Die Dampfmaschine ist eine der größten Erfindungen unserer Zeit.

Sold out

The 'Sophie' balancing machine represents a steam engine as it was initially used during the period of industrialization. This model is equipped with the Watsche parallelogram, which is used for a straight piston rod guide. The feed water pump connected to the balancing beam can be made functional. All required parts (material & Grafi:Sil valve balls) are included in the scope of delivery. The model machine can run smoothly and elegantly at 0.3 to 0.5 bar. The balancing machine is a special feast for the eyes, especially at low speeds. With this kit you can build a beautiful live steam system. The 'Sophie' is also ideal as a showcase or desk model.

All materials required to build the balancing machine 'Sophie', model building screws and accessories are included in the kit included. All milled parts are prepared to such an extent that they only need to be deburred and possibly drilled.

To build the balancing machine, you will need a lathe, a small drill and a gas burner for soldering larger parts. There are also hand tools that should be in every “steam engine workshop” (tap M2, M3, M4, die M2, M3, Reamer 3H7, 4H7, 6H7) Files and a drill set are necessary.Dimensions of balancing steam engine "Sophie" with base plateLength: 260mm

Width: 120mm

Height: 180mm

Flywheel D.: 100mm

Piston D.: 16mm

Stroke: 22mm

Included in the delivery are:

finished milled parts

Raw material for the turned parts

Raw casting for the flywheels

Raw casting part for balancer

Material & Valve ball for producing a feed water pump

Milled wooden base plate

All required screws, nuts and ball bearings

Drawings of balancing machine 'Sophie' (11 sheets) and construction instructions (6 sheets)

Product number:

2021

The half-balancing steam engine is a further development of the actual balancing steam engine. It was developed to reduce the space required by the steam engine while maintaining the same performance. The model has a 140 mm flywheel and a total height including the base plate of 190 mm. In this model, the balancing beam consists of two brass parts that have already been machined on the CNC milling machine. All assemblies are mounted on a base plate that has already been engraved. The flywheel is included in the material kit as a cleanly cast raw part.

All materials, screws and accessories required to build the steam engine are included in the kit. All milled parts are prepared to such an extent that they only need to be deburred and possibly drilled. To build the steam engine, you need a lathe, a small drill and a gas burner for soldering larger parts. You also need hand tools, which should be in every “steam engine workshop”, taps M2, M3, M8x0.75, dies M2, M3, M8x0.75, reamer 3H7, 4H7, 6H7, 8H7, files and a drill set. p>

Dimensions of half-balanced steam engine Grasshopper with base plate

Length: 240mm

Width: 110mm

Height: 190mm

Flywheel D.: 140mm

Piston D.: 16mm

Stroke: 27mm

Included in delivery are: finished milled parts

Raw material for the turned parts Raw casting for the flywheels Material & Valve ball for producing a feed water pump Engraved aluminum base plate All required screws, nuts and ball bearings Drawings 21 sheets) and construction instructions (5 sheets)

A detailed Construction report of the half-balanced steam engine can be found in our Bengs model building magazine. On the page you will find many pictures and texts with details and suggestions on how the components of the steam engine can be manufactured.

Product number:

2250