Kompression

Als Kompression oder Verdichtung beschreit das zusammenpressen eines Körpers egal ob flüssig, gasförmig oder fest. Meistens geht es allerdings wenn von Kompression die Rede ist um die Verdichtung im Brennraum von Verbrennungsmotoren. Bei Stirlingmotoren oder Flammenfressern findet auch eine Verdichtung der Luft im Zylinder statt. Ob Kompression vorhanden ist lässt sich bei Modellbau Motoren leicht überprüfen in dem man dem Motor, egal ob Verbrenner, Stirling oder Flammenfresser von Hand durchdreht. Wenn man einen Widerstand spürt der durch das zusammenpressen der Luft im Zylinder endteht spürt man die Kompression. Spürt man nichts ist es sehr wahrscheinlich das der Motor einen Defekt oder Fehler hat und nicht laufen wird. Bei Automotoren kann man die Verdichtung sogar mit einem Kompressionsmessgerät messen.

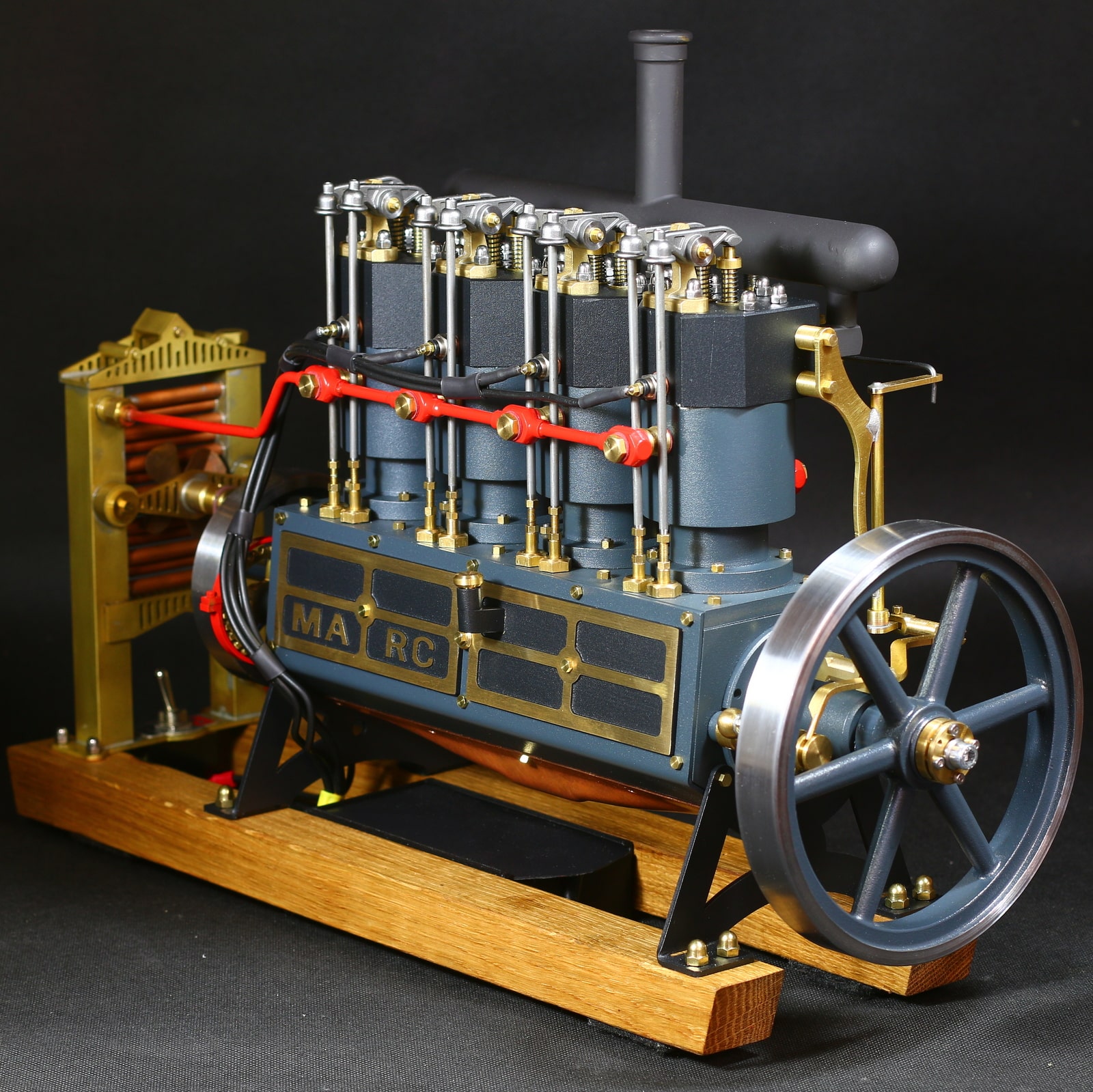

The 4-cylinder in-line engine "Marc" is based on a historical model. The model was a four-cylinder in-line engine that was manufactured by the American company Holt at the beginning of the 20th century. This engine was mainly used in bulldozers and tracked tractors. This engine was available in 2, 4 and 6 cylinder versions. In 1925, the Holt company became the Caterpillar company, which still exists today. The engine does not consist of a cast engine block, as was usual later, but still has individual cylinders. This design is visually very appealing and makes it possible to offer the engine as a material kit.

Speed control via centrifugal governor

Carburetor with adjustable throttle valve

Cooling circuit with cooling water pump

Cooler with fan

With the 4-cylinder in-line engine "Marc" material kit, you can build a fully functional combustion engine yourself. The material kit contains all the necessary parts including the ignition. The engine has a functioning speed control using a centrifugal governor. A cooling water pump pumps water through a radiator, where the cooling water is cooled down by the fan and then flows back into the cylinder jacket. The engine is equipped with glow plugs. The glow plugs come with four Batteries operated. All components for producing the ignition are included (batteries are not included).Dimensions of the model combustion engine 'Marc':

Height with wooden base: 310mm

Length: 450mm

Width: 180mm

Piston diameter: 23mm

Flywheel D.: 1x140mm 1x80mm

Speed speed: 200-1000 rpm

Weight: 9.1kg

The engine stands on two oak runners. The engine block is screwed together from milled parts. The base plate for the cylinders is made of steel, the bearing blocks that hold the crankshaft are made of aluminum. This unit is then provided with finished lasered and folded sheets. The cylinder sleeves are made of brass, the inside diameter no longer needs to be machined. The cylinder head and cylinder are included as material sections and must be machined on the lathe. The remaining components are mainly made of brass. The crankshaft is made from individual segments. No milling machine is required to produce the crankshaft either. It can be built entirely on the lathe. Further information can be found in our build report for the four-cylinder engine. The two flywheels are available in the quality we know. Both flywheels are made of cast steel.

The speed of this model is controlled via the carburettor. You can regulate the amount of air supplied. The carburettor is connected to a centrifugal governor via a linkage. This means you can set the engine to a desired speed, which is then maintained under load using the centrifugal governor.

Here you will find an extensive construction report of the four-cylinder internal combustion engine Marc< /a> with lots of pictures and additional texts.

Here you will find extensive assembly instructions for the combustion engine On the page you can see how you have to put all the manufactured parts together.

Here you will find extensive instructions for the Commissioning and operation of the four-cylinder engine Marc

All materials required to build the internal combustion engine "Marc" screws, nuts, springs and ignition parts are included in the kit. All milled parts are prepared so that they only need to be deburred and possibly drilled. To build the vertical stationary motor, a lathe, a drill and a gas burner for soft soldering are required. The following hand tools are also required (tap M2, M3, M4, M5, 6x0.75, M8x0.75, M10x1 die M2, M3, M5, M6x0.75, M8x0.75, M10x1 reamer 4H7 6H7, 8H7, 10H7) Files and a drill set are necessary. All you need to wire the ignition is a pair of side cutters, wire strippers and a soldering iron.

If you would like to find out in advance what steps you will take to make this internal combustion enginehave to be carried out, take a look at the construction report of the 4 cylinder combustion engine "Marc" material kit in our Bengs model building magazine. On this page you can see the illustrated report on how the stationary motor material set is processed.The scope of delivery includes:

finished CNC milled milled parts

Raw material for the turned parts

Rough casting part for the flywheels

2 runners made of oak wood

All required screws, nuts, gears and seals

Drawings of the internal combustion engine "Marc" (36 sheets) and construction instructions (8 sheets)

Glow plugs, cables, cable clamps, battery compartment for the ignition

Laser parts for stands and fairings

Product number:

2270

The combustion engine “Little Karl” is, as the name suggests, the small version of our popular combustion engine Karl. With this kit, particular emphasis was placed on the fact that it can be made in a small hobby workshop with a small lathe. Thanks to its simple construction, this model is also suitable for beginners in technical model making. In contrast to the large stationary engine Karl, this model does not have an ignition with a spark plug but rather a Glow plug. This circumstance makes both the construction of the model and its operation easier because the ignition timing does not need to be adjusted. Of course, this model also has speed control via Hit & Miss control.

The combustion engine “Little Karl” with glow plug has a stable frame made of milled brass parts. The crankshaft is guided in two gunmetal plain bearings. The cylinder sleeve consists of a precision brass tube that no longer needs to be processed inside. An aluminum piston runs in the tube. The cylinder head and cooling jacket are also made of aluminum. Most other components such as the carburettor, tank, rocker arms and controls are made of brass. The entire motor is mounted on an aluminum base which in turn rests on two oak wooden runners. The two 80mm flywheels and the pulley are made of cast steel using the lost wax casting process and are of excellent quality. All materials required to build the combustion engine "Little Karl", such as screws, springs and ignition parts, are included in the kit. All milled parts are prepared so that they only need to be deburred and possibly drilled. All turned parts are included in the kit unmachined and must be manufactured according to the drawing.

To build the Hit & Miss Motors requires a small lathe, a drill and a gas burner for soft soldering. The following hand tool is also required (tap M2, M3, M4, tap UNEF1/ 4 x 32, Dies M4, M6, reamer 3H7, 5H7, 6H7, 8H7) files and a drill set are necessary. All you need to wire the glow plug is a pair of side cutters, wire strippers and a soldering iron. You also need a baby battery with at least 3000 mAh. The battery is not included in the kit but can be ordered from us.

If you would like to find out in advance which work steps you have to carry out when manufacturing this combustion engine, take a look at our Bengs model building magazine Construction report of the combustion engine "The Little Karl" with glow plug. On this page you can see the illustrated report on how the stationary motor material set is processed.

Dimensions of the model combustion engine 'Karl':

Height with wooden runners: 135mm

Length overall: 200mm

Width overall: 120mm

Length without runners: 190mm

Piston diameter: 20mm

Flywheel D.: 80mm

Speed: 600-1500 rpm

Weight of the finished model: 1.8kg

Hit & Miss Regulation

With the hit & With this control you can limit the maximum speed of the engine. If the engine has reached too high a speed, a slide prevents the exhaust valve from closing. This means the engine runs freely. No compression can occur in the cylinder chamber and the engine neither sucks in fresh gasoline nor ignites the air-fuel mixture. The Hit & Miss regulation is called suspension regulation in German. The misfire control was mainly used in the USA by various companies for internal combustion engines from 1890 to 1940.

The scope of delivery includes:

finished CNC milled milled parts

Raw material for the turned partsRough casting part for the flywheels 80mm Raw casting part for the belt wheel Two wooden runners made of oak All required screws, nuts, gears and sealing rings Drawings of the combustion engine "Little Karl" (24 sheets) and construction instructions (11 sheets) Switch, battery compartment, cable and glow plug (Battery Baby battery not included is available from us

Product number:

2205

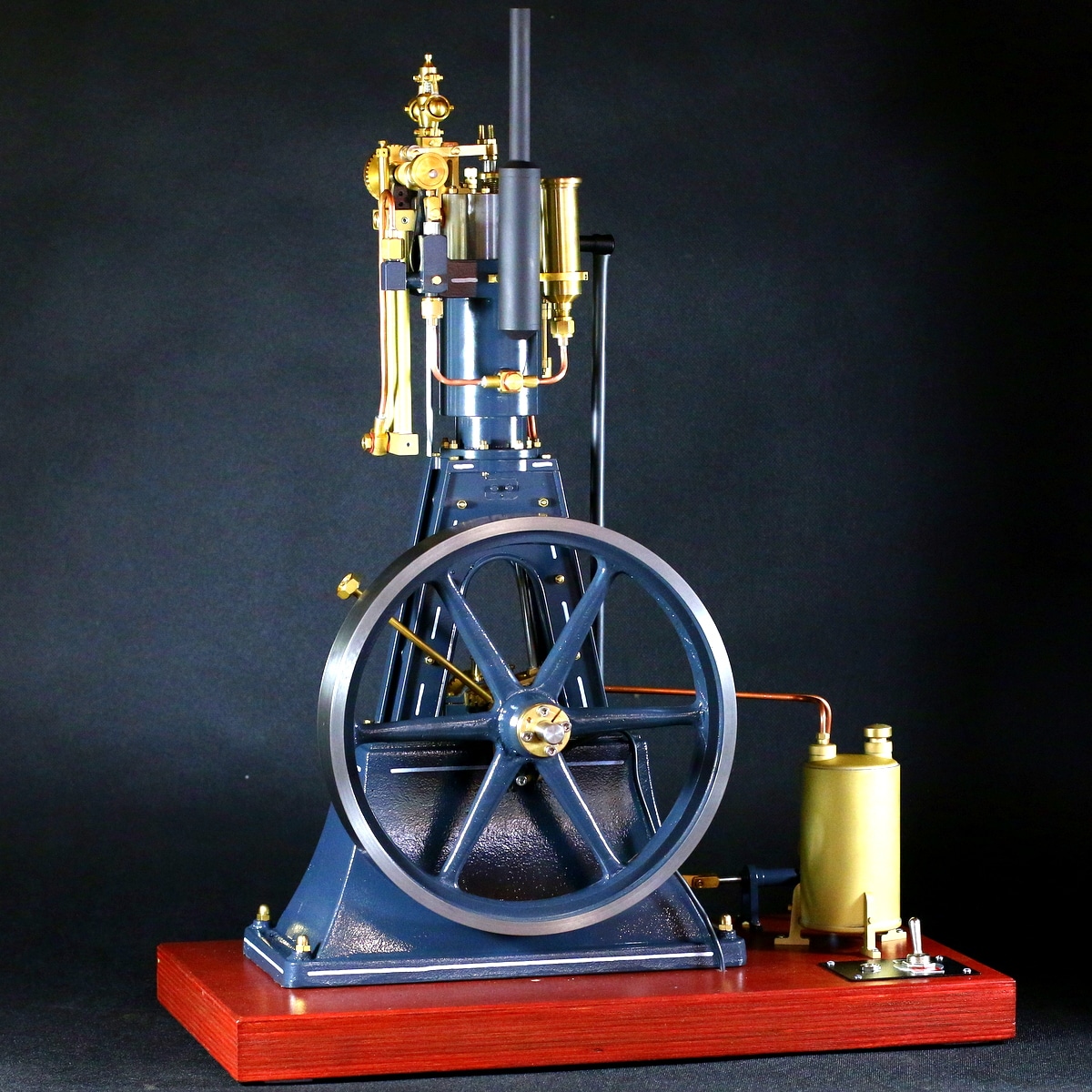

The Jonas vertical combustion engine was based on the appearance of the early diesel engines that were created at the beginning of the 20th century. A frame that has the shape of an A was typical. In addition, the early diesel engines were mostly long-stroke engines, which resulted in a slim and tall design. The overhead camshaft, which was driven by a long vertical shaft, was also typical. Back then, as now in our model, the speed was controlled via a centrifugal governor mounted on top of the vertical shaft. Our combustion engine runs on gasoline, but operation on diesel is not possible.

Speed control via centrifugal governor

Carburetor with adjustable throttle valve

Cooling circuit with cooling water pump

Fuel pump delivery rate adjustable

Ignition timing adjustment

Camshaft drive via screw wheel 45°

With the material kit for the water-cooled 4-stroke engine "Jonas" you can build a fully functional internal combustion engine yourself. The material kit contains all the necessary parts including the ignition. The engine has functioning speed control using a centrifugal governor. A cooling water pump pumps water through a radiator into the cylinder jacket and back again. The engine also has a fuel pump that pumps the fuel towards the carburettor into an intermediate tank. The pumping volume of the fuel pump can be adjusted as required. The breaker ignition is located in the cast base. The ignition is supplied with voltage via a 12 V 2 A power supply. The power supply is also included.Dimensions of the model combustion engine 'Jonas':

Height with wooden base: 500mm

Dimensions of the base plate: 350mm x 210mm

Piston diameter: 25mm

Flywheel D.: 200mm

Speed speed: 200-600 rpm

Weight: 11.8kg

The machine base of the vertical stationary motor is a heavy gray cast iron base. This heavy base gives the model sufficient stability. The piston of the combustion engine is also made from gray cast iron round material. In this engine the piston also has a piston ring. The piston ring is already included in the kit. A hydraulic cylinder tube is used as a cylinder, which is already finished on the inside and has an excellent surface. The cylinder head is made of aluminum, the cooling jacket is hollow and is flushed with cooling water via a cooling water pump. The 200mm flywheel is made of gray cast iron and can be ordered pre-machined upon request. Most of the attachments and the machine frame are made of brass.Speed control

The speed of this model is controlled via the carburettor. By being able to regulate the amount of air supplied. The carburettor is connected to a centrifugal governor via a linkage. This means you can set the engine to a desired speed and this is maintained even under load using the centrifugal governor.

All materials required to build the internal combustion engine "Jonas" screws, nuts, springs and ignition parts are included in the kit. All milled parts are prepared so that they only need to be deburred and possibly drilled. To build the vertical stationary motor, you need a lathe, a drill and a gas burner for soft soldering. The following hand tools are also required (tap M2, M3, M4, M6x0.75, M8x0.75, M10x1 die M2, M3, M4, M6x0.75, M8x0.75, M10x1 Reamer 3H7, 4H7 6H7, 8H7, 10H7) Files and a drill set are necessary. All you need to wire the ignition is a pair of side cutters, wire strippers and a soldering iron.

If you would like to find out in advance which work steps you have to carry out when manufacturing this combustion engine, take a look at our Bengs model building magazine Construction report of the vertical stationary engine “Jonas” at. On this page you can see the illustrated report on how the stationary motor material set is processed.The scope of delivery includes:

finished CNC milled milled parts

Raw material for the turned parts

Raw casting part for the flywheel (optionally also completely turned)

Base plate birch multiplex

Cylinder sleeve

Product number:

2230M