Lexicon: P

Pulverbeschichtung

Bei der Pulverbeschichtung wird das Pulver, Duroplast- oder Thermoplastpulver, auf die zu beschichtenden Werkstücke aufgebracht und durch Wärmeeinwirkung verschmolzen. Bei den Duroplastpulvern findet bei der Wärmeeinwirkung zusätzlich eine Vernetzung des Beschichtungspulvers statt. Es bildet sich ein geschlossener Lackfilm aus. Die Pulverlacktechnologie hat sich seit den ersten Anfängen in den 60er Jahren zu einer produkt- und verfahrenstechnischen Alternative zur Nasslackbeschichtung entwickelt. Das Anwendungsgebiet von Pulverlacken ist sehr breit gefächert. Es werden Bauteile aus den Bereichen Fahrzeug- und Maschinenbau sowie der Fassadentechnik beschichtet. Die Oberflächen der zu beschichtenden Bauteile und Werkstücke werden je nach Werkstoff und Einsatzzweck unterschiedlich vorbehandelt. Es wird zwischen zwei verschiedenen Pulverbeschichtungs-verfahren unterschieden:

- elektrostatische Pulverbeschichtung (Tribo)

- Wirbelsinterverfahren (Korona)

Die Pulverbeschichtung wird auch sehr Erfolgreich im Modellbau eingesetzt, mit Hilfe verschiedenster Verfahren, werden auch kleinste Teile Pulverbeschichtet. Gerade im technischen Modellbau lassen sich mit der Tribo Pulverbeschichtung wie zum Beispiel Bengs Modellbau Pulverbeschichtungssystem herausragende Ergebnisse erzielen. Grade bei Materialien wie Messing auf dem Nasslacke nicht besonders haltbar sind erzielt man durch Pulverbeschichten sehr gute Ergebnisse. Die Pulverbeschichtung wird an größten so wie auch an kleinsten Bauteilen praktisch angewendet.

With this powder coating machine, you can easily apply powder coatings to materials such as metal, non-ferrous metals and aluminum. In addition, you can also use the powder coating system to coat non-conductive materials such as ceramic or glass powder coated. The special feature of this powder coating device is that the powder is only statically charged and no high voltage is required. This powder coating plant does not require a power connection. All you need is a compressor. With this device, you are able to produce a professional powder coating in your own workshop. A powder-coated component is significantly more robust and durable than a painted component.

This powder gun is a tribo powder coating system. The powder is statically charged by friction in the course of the gun. Electrostatically charged, it adheres to the workpiece. Through this effect, you can coat a variety of materials. Charging is effected by the powder particles touching the wall of the barrel of the powder gun, thereby dissolving electrons from the Teflon ™ barrel. The separation of the powder lacquer particles from the spray gun takes place more quickly than the charge can redistribute. As a result, the powder particles remain charged and stick to any material. You do not need any additional electricity for the Tribo process. The enclosed plug is only the earth connection of the device.

Includes:

AlPowder coating gun with EU (Schuko) ground plug

250ml powder container

Funnel for a simple loading of powder into a powder cup

14 page user guide in English with multiple pictures that will guide you through a powder coating process safely.

Powder coating is the process when powdery plastic particles (usually polyester or polyuretan) are electrostatically applied to a clean metal surface using a powder coating device. The process is used throughout the industry to create a durable, professional finish. The principle is quite simple, after the preparation and the degreasing of the component, the powder is positively charged by the gun. Similar to a TV screen attracts dust, the component now attracts the charged powder cloud. In the next step, the powder-coated component is placed in an electric furnace. Please note that the oven is no longer used for food preparation. Most powders require about 15 minutes of baking at 180 ° C. The average time from the powder coating to the ready-to-install component takes about 30 minutes.

What else is needed (not included in the set)

Compressor with pressure regulator

extension hose

Oven alternatively small pizza oven

FFP2 protective mask

safety goggles

Well ventilated workplace

Advantages of coating:

Extremely robust and abrasion resistant

Without drying time immediately ready for use

Optimal corrosion protection

Environmentally friendly as there are no solvents

Absolutely uniform surface quality

Elastic coating e.g. For springs

Product number:

33003

You will get powder coating powder in facade quality in 250g bottles. The coating powder is filled into plastic bottles so that the powder remains permanently dry. With the powder you can create an easy to clean, weather and UV-resistant and extremely durable surface coating. The powder is suitable both for powder coating with corona and with tribo coating devices. The coating powder has excellent light and weather resistance. It also has a good elasticity so you can even coat feathers. The powder adheres to all surfaces. All powder coatings available at our company are suitable for corona powder coating systems as well as for tribo powder coating systems.

The following coating powder colors are available:

RAL 1003 Signal Yellow Glossy (250g)

RAL 3000 Fire Red Glossy (250g)

RAL 5005 Signal Blue Shining (250g)

RAL 6020 Chromium oxide green Glossy (250g)

RAL 7001 Silbergrau Shining (250g)

RAL 7016 Antrazite Gray Glossy (250g)

RAL 9005 Deep black Glossy (250g)

RAL 9005 Deep black Deep matt (250g)

RAL 9010 Pure White Glossy (250g)

Transparent colorless high gloss (250g)

Chrome Metallic Gloss (250g)

Product number:

330000M

Variants from €20.10*

Tip

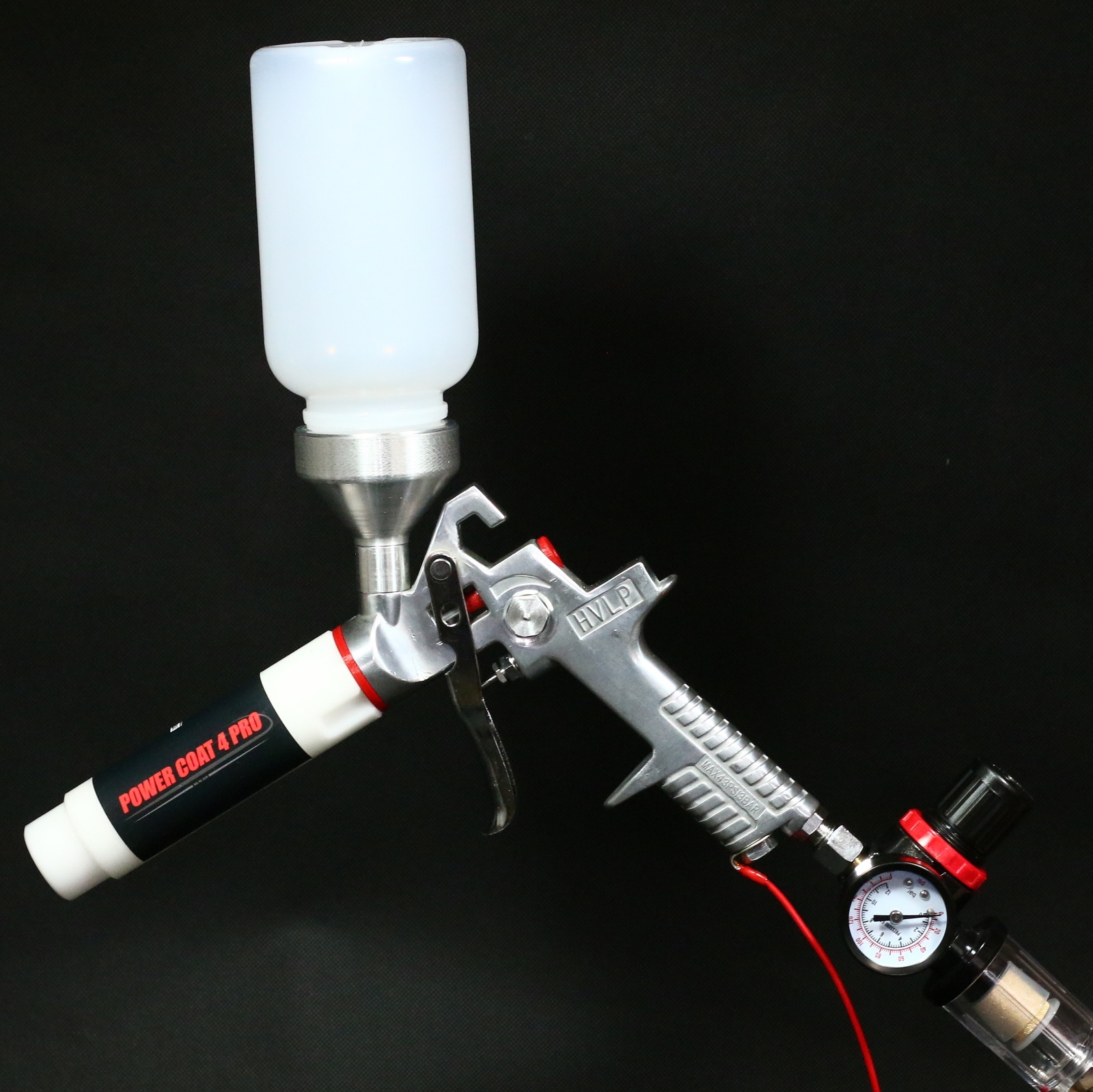

The Power Coat 4 PRO is a high-quality powder coating system for small to large areas. You will receive the powder coating gun in a high-quality plastic case in which everything has its place. This powder gun is significantly more robust than our standard powder coating system. This makes it suitable for use in commercial businesses and for ambitious DIY enthusiasts.

Advantages of powder coating over painting:

Ready to use immediately without drying time

Extremely robust and abrasion-resistant

Optimal corrosion protection

Environmentally friendly as no solvents

Absolutely uniform surface quality

Coating remains elastic e.g. for springs

The Power Coat 4 PRO has a 500 ml powder container so that even larger areas can be coated with powder without having to refill the coating powder in the meantime. Another advantage of this device is that there is a water separator and a pressure regulator directly on the powder gun. This makes setting the correct pressure much easier.

Scope of delivery:

Powder coating device with Schuko earthing plug, stable ground clamp, water separator and pressure regulator

Two 500ml powder containers to screw into the coating gun

Funnel for easy filling of the powder containers

Sturdy case for storage

14 pages German operating instructions

The Power Coat 4 PRO powder coating device is suitable for many different powder coating applications. With this powder coating system, even the smallest components can be easily powder coated. Even larger parts are no problem thanks to the 500 ml powder container. Our powder coating systems are very often used in the restoration of old motorcycles or cars. With this system it is possible to coat entire motorcycle frames or rims with powder varnishfor coating. The result is indistinguishable from industrial powder coating. Powder coating is also very often used in technical model making because the finished surface is extremely robust, scratch-resistant and provides good corrosion protection.

Application examples

powder coating of vintage car parts

Powder coat motorcycle parts

Powder coat rims

Powder coating of small parts in technical model making

This powder gun is a Tribo powder coating system. The powder becomes statically charged in the barrel of the gun due to the friction on various materials. The device is connected to the earth conductor of the socket via a ground terminal and a Schuko plug, which means the component is grounded. Due to the electrostatic charge generated during the run, the coating powder adheres to the workpiece. This effect allows you to coat a variety of materials. The charging occurs when the powder particles touch the wall of the barrel of the powder gun, causing electrons to be released from the Teflon™ barrel. The powder paint particles are separated from the spray gun faster than the charge can be redistributed. This means that the powder particles remain charged and stick to any material. You do not need any additional electricity for the tribo process. The included plug is only the ground connection of the device.

Power Coat 4 PRO can process all coating powders that are suitable for Tribo systems.

Here in our online shop you will find suitable spare parts for the powder coating system. p>

Coating wood, tiles and glass

In contrast to conventional powder coating systems, this powder gun coating system can also be used to coat wood, tiles and glass. Since these materials are not conductive, the ground terminal cannot be connected here. This makes applying the powder a little more difficult. You should first make a sample to test the properties of the material and its behavior during powder coating.

What else is needed (not included)

Compressor

Extension hose

oven for burning (min. 200c ° from a small household oven to our)

Product number:

3314