Lexicon: V

Verdrängerzylinder

Der Verdrängerzylinder ist ein Bauteil in einem Stirlingmotor. In im läuft der Verdrängerkolben. Der Zylinder hat eine Warme Seite an der die Wärmeenergie zugeführt wird und eine Kalte Seite die möglichst kalt seien sollte und durch Luft oder Wasser zusätzlich gekühlt wird. Man spricht dann von luftgekühlt oder wassergekühlt. Der klassische Stirlingmotor hat zwei Bereiche:

- Der Verdrängerbereich bestehend aus Verdrängerzylinder und Verdrängerkolben

- Der Arbeitsbereich bestehend aus Arbeitskolben und Arbeitszylinder

Die Aufgabe des Verdrängerkolbens ist es die erwärmte Luft im Verdränungszylinders von der warmen zur kalten Seite zu verdrängen und umgekehrt. Der Verdrängerkolben liegt nicht am Zylinder an sondern hat umlaufend einen Spalt so das die verdrängte Luft um den Kolben herumströmen kann. Je leichter ein Verdrängerkolben je besser ist das für dem Lauf des Stirlingmotors, entweder man erreicht ein geringes Gewicht durch die Verwendung von geringer Wandstärke zum Beispiel dünnes Kupferblech oder Stahlblech oder es werden leichte Materialien eingesetzt wie zum Beispiel Aluminium oder Stechschwamm aus dem Floristenbedarf.

The Stirling engine 'Laura' has parallel cylinders; this type is called gamma type. The engine is a visually very appealing showcase and demonstration model which can be put into operation at any time and anywhere.

The Stirling engine 'Laura' material kit is constructed according to the well-known BENGS model building principle. All milled parts are prepared to such an extent that they only need to be deburred and possibly drilled. The turned parts are unprocessed. The flywheel is pre-turned and milled to such an extent that it can also be finished on a small lathe.The scope of delivery of the Stirling engine Laura material kit includes:

Finished milled parts

Raw material for the turned parts

very clean 80mm cast flywheel

Milled oak base plate

All required screws, nuts, Duran glass tubes, Ball bearings and O-rings

Construction plan Stirling engine Laura drawings (7 sheets) and construction instructions (3 sheets)

Dimensions Stirling engine Laura:

Base plate: 140mm x 100mm

Flywheel: 80mm

Total height: 105mm

Working piston: 10mm

Displacer piston: 13mm

To build the Stirling engine "Laura" material set, you will need a small lathe, a small drill and a gas burner for soldering small parts. Otherwise there are hand tools that should be in every “steam engine workshop” (Tap drill M2, M3, cutting die M2 and M3, reamer 3H7, 6H7, 10H7, files, drill set) are necessary.

Product number:

2062

Tip

Average rating of 5 out of 5 stars

The original Britain, America and France had introduced several notable hot air engines by 1850. Surprisingly, Germany had not produced any significant innovations in this area up to this point, it was not until 1867 that the German Wilhelm Lehmann produced a significant innovation in the field of hot air machines. A late innovation, but an impressive one: the Lehmann air expansion engine!The model Stirling engine Rainer

The model of the Lehmann Stirling engine has a total length of 285 millimeters. When designing our Stirling engine, we tried to keep it as close to the original as possible. However, it is not a 100% copy of the original. Our model is operated with an alcohol burner. The burner is firmly screwed to the oak base plate. The cooling jacket, which was a solid casting in the original, is assembled from several milled brass parts and soft-soldered. Just like the original Lehmann Stirling engine, the model has a functional centrifugal governor that can regulate the speed of the hot air machine. As with the original, the centrifugal governor opens a valve that allows the air in the Stirling's working chamber to escape. The 140 mm diameter flywheel is made from a very clean cast steel. In addition, the Stirling engine has a 48mm pulley that could be used to drive small drive models, for example.Speed control via centrifugal governor This Stirling engine has a working centrifugal governor. When the speed is sufficient, the balls of the regulator rise. This moves a lever that operates a valve. If the valve is opened, the working air can escape from the displacement cylinder. Due to the reduced pressure, the Stirling process no longer works optimally and the engine reduces its speed. To set the desired speed, you can adjust the spring tension of the valve using a handwheel during operation.Dimensions of the model Stirling engine Base plate: 255mm x 120mm Flywheel: 140mm Pulley: 48mm Total height: 210mm Working piston: 28mm Displacer piston: 25mm Length overall: 285mmThe “Rainer” Stirling engine material kit is included in delivery Wooden base plate Finished milled parts Brass, steel, stainless steel and silver steel Raw material for the turned parts Cylinder sleeve made of precision tube flywheel All required screws, nuts, gaskets, grub screws and wick Construction plan model Stirling "Rainer" drawings (14 sheets) and construction instructions (9 sheets)

Product number:

2280

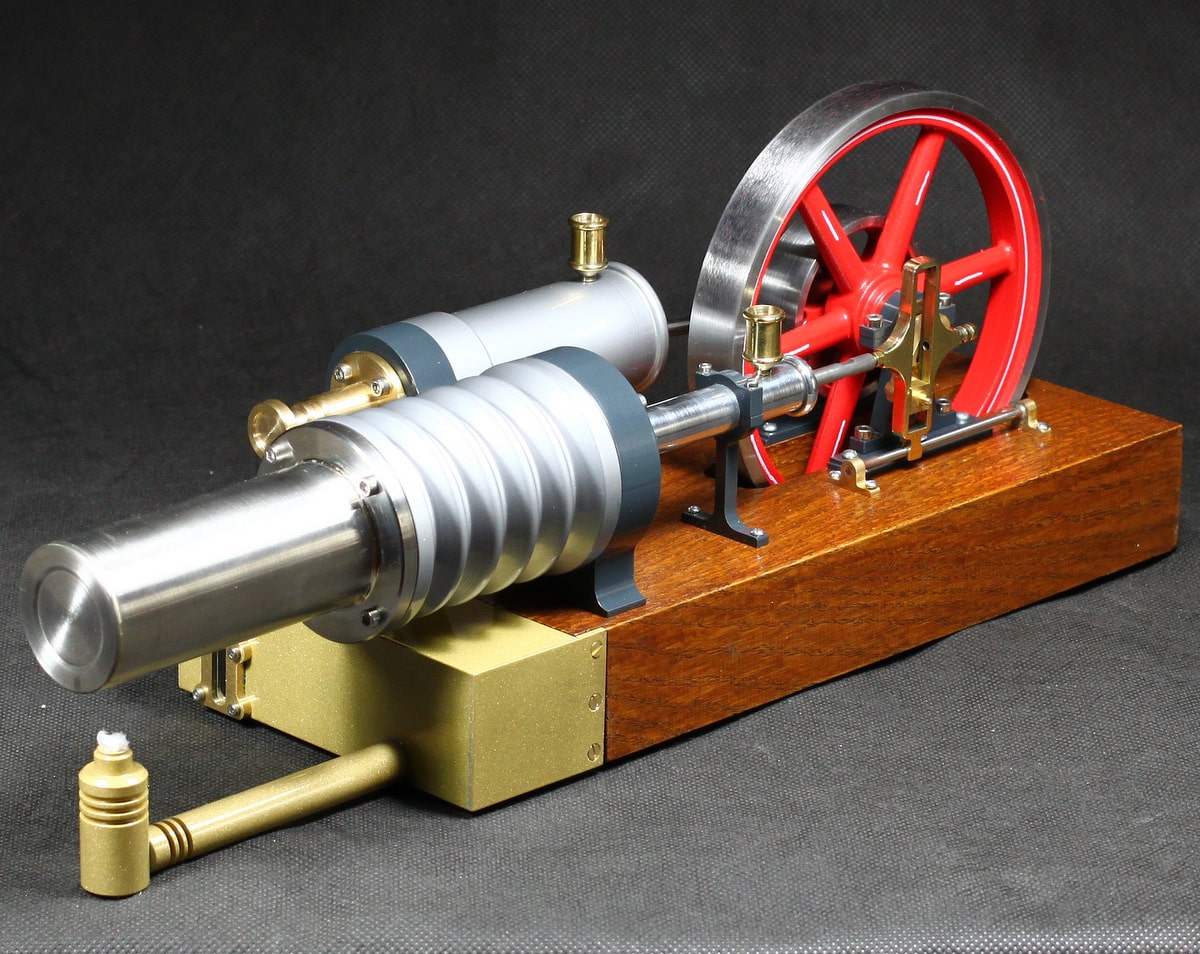

The Stirling engine "The Great Laura" is similar in design to a horizontal plank hot air engine from 1910. Like every Stirling engine, this horizontal, air-cooled heat engine has two cylinders with pistons, the displacement cylinder and the working cylinder. The working cylinder is made of steel, the displacement cylinder is made of aluminum with a 60mm diameter due to better thermal conductivity. In addition, the displacement cylinder is equipped with cooling fins to ensure the machine runs for as long as possible. Like its historical model, the hot air engine has a flywheel and a pulley. The modelThe Stirling engine As you can tell from the name, “The Big Laura” is a large version of our very successful “Laura” Stirling engine kit. The size of this model brings with it some advantages. Due to its large surface area, the Stirling engine can dissipate heat better and therefore run longer. The tank of the Stirling engine "The Big Laura" is extra large. A tank full of denatured alcohol lasts 8-10 hours depending on the size of the flame. In addition, significantly lower speeds are possible with this large Stirling engine than with small model Stirling engines. But even high speeds are no problem for the model. The speed of this hot air motor can be controlled using an adjusting wheel. The burner is firmly connected to the model and the base plate. A 140mm flywheel and a pulley in our well-known cast steel quality run on the drive shaft. The working cylinder consists of a hydraulic cylinder tube and no longer needs to be processed on the inside. The included oak base plate is also pre-milled. The blueprint and construction instructions included with the Stirling engine are very extensive, detailed and easy to understand. For the model maker who has always wanted to build a large Stirling engine himself, the Stirling engine "The Big Laura" is a well-suited model. Dimensions of the model Stirling engine Base plate: 255mm x 120mm Flywheel: 140mm Pulley: 56mm Total height: 120mm Working piston: 30mm Displacer piston: 35mm Overall length: 410mm < span style="letter-spacing:0px;">Included in the scope of delivery of the material kit Stirling engine "The Great Laura" are Milled wooden base plate

Finishedmilled milled parts

Brass, steel, stainless steel and silver steel Raw material for the turned parts Cylinder sleeve made of hydraulic cylinder tube Flywheel and pulley made of cast steelAll required screws, nuts, gaskets, grub screws and wick Construction plan model Stirling "The big Laura" drawings (14 sheets) and construction instructions (9 sheets) All materials, screws and accessories required to build the Stirling engine "The Great Laura" are included in the kit. All milled parts are prepared to such an extent that they only need to be deburred and possibly drilled. To build the Stirling you will need a medium-sized lathe, a column drill and a gas burner for brazing and soft soldering. There are also hand tools that should be in every "model making machine shop" (tap M2, M3, M4, M8x0.75, M10x1 die M3, M8x0.75, M10x1 reamer 3H7, 4H7, 5H7, 8H7, 10H7) files and a drill set is necessary. You can find a detailed construction report for this model in our Bengs model building magazine. In the Construction report of the Stirling engine “The Great Laura” you will find lots of pictures and explanatory texts. This means you can find out in advance about the work that needs to be done. But the Stirling engine construction report can also help you during construction.

Product number:

2190

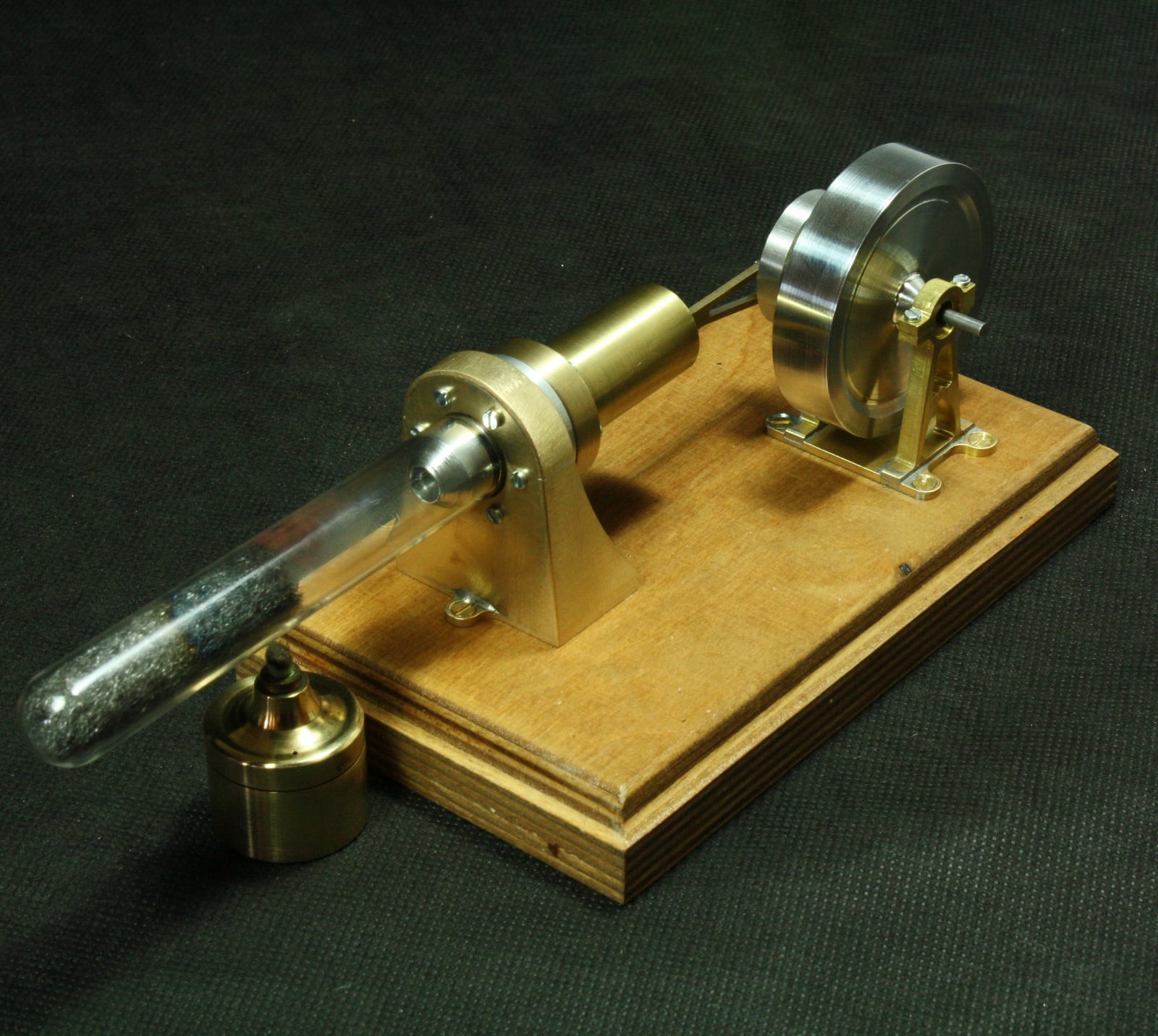

Our model Rufus is a model of a thermoacoustic Stirling (Lamina Flow Stirling). The construction of the thermoacoustic Stirling engine is very simple. In Rufus, the working piston is moved by a thermoacoustic effect. A thermoacoustic effect occurs when air is heated in a tube and caused to vibrate using an exciter source (e.g. steel wool) so that a standing wave is formed in the tube (Rijke tube). As with the Stirling engine, there is also the cycle of expanding and contracting air (gas). A comparison with the Stirling engine is also possible in that it is a closed system, although the thermoacoustic Stirling does not use a displacer piston. This is what makes the design of the engine so simple. The thermoacoustic Stirling engine Rufus runs almost silently. It is heated with a small burner filled with spirit. The working piston is made of graphite and does not need to be lubricated.

The Stirling engine 'Rufus' material kit is constructed according to the well-known BENGS model building principle. All milled parts are prepared to such an extent that they only need to be deburred and possibly drilled. The turned parts are unprocessed. The flywheel can also be made on a small lathe.

The scope of delivery includes:

Finished milled parts

Raw material for the turned parts and graphite pistons

Raw material flywheel (aluminum)

Milled wooden base plate made of oak

Material for the burner

All required screws, nuts, glass tubes, fiberglass wick, ball bearings and O-rings

Construction plan Stirling engine Rufus drawings (6 sheets) and construction instructions (2 sheets)

Dimensions Thermoacoustic Stirling engine Rufus

Base plate: 170mm x 100mm

Flywheel: 60mm

Total height: 88mm

Total length: 255mm

Working piston (graphite): 18mm

To build the thermoacoustic Stirling engine Rufus material set, you will need a small lathe (min. Opti D180 x 300), a small drill and a gas burner for soft soldering. Otherwise, hand tools, which should be in every “steam engine workshop”, are required (M2 tap, 3H7, 6H7 reamer, files, drill set, screw locking adhesive).

Product number:

2120